NOTE: After replacing the diesel particulate filter differential pressure sensor it is necessary to reset the parameters for the diesel particulate filter differential pressure sensor. In this regard, always refer to the instructions in the current Service Literature.

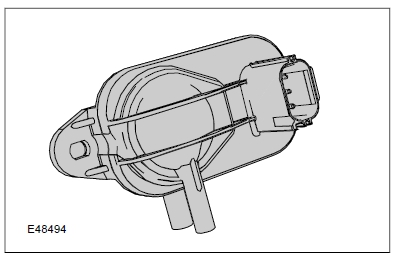

The diesel particulate filter differential pressure sensor measures the current pressure differential upstream and downstream of the diesel particulate filter in the exhaust gas stream.

1 Diesel particulate filter

2 Pipe connections – diesel particulate filter differential pressure sensor

3 Oxidation catalytic converter

For this purpose, there is a pipe connection upstream and downstream of the particulate filter.

The readings are converted by the diesel particulate filter differential pressure sensor into a voltage signal and transmitted to the PCM.

The soot particles and ash collected in the diesel particulate filter result in a pressure change of the exhaust gas upstream and downstream of the diesel particulate filter. The altered pressure value owing to the ash/soot load is used by the PCM as an input parameter for determining soot and ash load.

Furthermore, a defective diesel particulate filter and the absence of a diesel particulate filter are detected via the diesel particulate filter differential pressure sensor.

Effects of faults

If the sensor is defective the PCM calculates the timing of the next regeneration.

Overloaded or blocked diesel particulate filter:

• From the engine’s operating conditions and from the input parameter of the diesel particulate filter differential pressure sensor, the PCM continuously calculates the load status of the diesel particulate filter.

• With an increasing ash/soot load, the engine torque is also reduced continuously. However, this is not noticeable by the driver. With an overloaded diesel particulate filter there is therefore no further intervention carried out by the PCM.

• With a blocked diesel particulate filter , only the glow plug warning indicator/fault lamp as well as the MIL are set.

Diagnosis

The monitoring system checks:

• the sensor for short circuit to ground/battery and open control loop.

• the measured sensor values for plausibility (comparison with the map data).

Via the diesel particulate filter differential pressure sensor, the monitoring system detects:

• an overloaded/blocked diesel particulate filter. (The pressure drop across the filter is too great and the differential pressure exceeds a calibrated maximum value.)

• a defective/missing diesel particulate filter. (The pressure drop across the filter is too low and the differential pressure falls below a calibrated minimum value.)