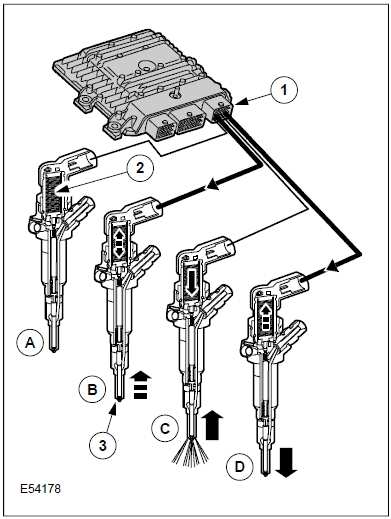

A Fuel injector closed

B Voltage pulse from the PCM: Start of charging phase, fuel injector begins to open

C Injection

D Voltage pulse from the PCM: Start of discharging phase, injection ends

1 PCM

2 Piezo actuator

3 Injector needle

The piezo-electrically controlled fuel injectors switch up to four times more rapidly than electro-magnetically actuated fuel injectors.

Actuation of the fuel injectors for fuel metering (start of injection and injected fuel quantity) is performed directly by the PCM, whereby the target rail pressure must be at least 150 bar during startup. A voltage pulse is required both for opening and closing the fuel injectors.

The initial charging voltage applied by the PCM for opening the fuel injectors is 70 V, however, this is increased to approx. 140 V within 0.2 milliseconds by the piezoelement. The charging current is approx. 7A.

The voltage pulse causes the individual peizoelements to press against one another, generating further voltage. During the charging phase, the piezo actuator expands (elastic tension) and opens the fuel injector needle. In order to end the injection process, a further voltage impulse is required from the PCM. The discharging time of the piezo actuator and consequently the closing time of the fuel injector needle is approx. 0.2 milliseconds.

Fuel injector actuation characteristic curve

A Injected fuel quantity for pilot injection

B Injected fuel quantity for main injection

1 Fuel injector needle lift (mm)

2 Actuation current (amps)

3 Voltage (V)

4 Crankshaft angle (CS degrees)

The various characteristic curves during pilot injection and main injection are shown in the illustration. In the case of vehicles with diesel particulate filters, any possible post-injections following the main injections during the regeneration process are comparable to the pilot injections. In order to operate the piezo actuator, a brief burst of current (charging current) is needed. During the injection phase, a voltage of approx. 140 V is maintained by the PCM by means of a capacitor. To reverse the expansion of the piezo actuator, a short burst of current in the opposite direction (discharging current) is generated. The discharging current causes the piezo actuator to return to its initial position and injection ends.

Note:

• As the injection is ended by means of the discharging current, the wiring harness connector of the piezo fuel injectors must on no account be detached when the engine is running.

• If the wiring harness connector is detached at the moment of injection, this leads to continuous injection and engine damage.

Effects of faults

rough engine running,

increased emissions of black smoke,

loud combustion noise (e.g. resulting from cut-off of the pilot injection)

reduced engine power output

Moreover, electrical faults lead to deactivation of cylinder balancing and limited anti slip regulation (no intervention in engine management).

Diagnosis

In the context of EOBD the PCM performs various electrical checks in the individual fuel injector electrical circuits.

Electrical faults in the fuel injectors are detected via the power consumption at the piezo actuator by means of the relevant output stage in the PCM.

The monitoring system is able to identify two types of malfunctions using several electrical tests:

• Fuel metering fault of all fuel injectors,

• Fuel metering fault of a single fuel injector

This works by monitoring the staged power supply of the fuel injectors (as described previously).

The power consumption of the piezo actuator (in relation to a defined time) indicates whether the actuator is working within its tolerances.

Deviations from the tolerance range result in uncontrollable fuel metering. This means that the injected fuel quantity and the injection timing can no longer be determined precisely.

This fault is therefore a MIL active fault, unless a fault of this kind leads to engine shutoff. In addition, the fuel injectors are checked for short circuit and open circuit.

Certain faults (e.g. short to positive) lead to the fuel injectors no longer being actuated.

Possible diagnostic trouble codes: P0200 to P0204; P0606; P1201 to P1204, P1551 to P1554.