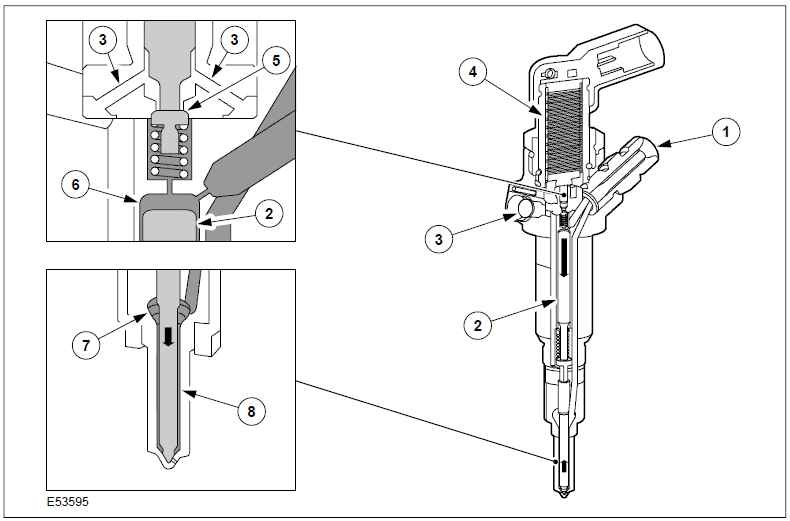

Fuel injector closed

1 High pressure feed line

2 Control piston

3 Fuel return

4 Piezo actuator

5 Valve mushroom

6 Control chamber

7 Nozzle prechamber

8 Injector needle

The fuel is fed at high pressure from the fuel rail via the high pressure feed line into the control chamber and the nozzle prechamber.

The piezo actuator is de-energized and the orifice for fuel return is closed by means of the spring-loaded mushroom valve.

The hydraulic force now exerted onto the fuel injector needle by the high fuel pressure in the control chamber via the control piston is greater than the hydraulic force acting on the fuel injector needle, as the surface of the control piston in the control chamber is greater than the surface of the fuel injector needle in the nozzle prechamber.

The needle of the fuel injector is closed (no injection).

Fuel injector opens

1 High pressure feed line

2 Control piston

3 Fuel return

4 Piezo actuator

5 Valve mushroom

6 Control chamber

7 Nozzle prechamber

8 Injector needle

9 Valve piston

The piezo actuator, which is energized by the PCM, expands (charging phase) and pushes against the fuel injector piston.

The mushroom valve opens the orifice which connects the control chamber with the fuel return line.

This results in a pressure drop in the control chamber and the hydraulic force acting on the fuel injector needle is now greater than the force acting on the control piston in the control chamber.

This causes the fuel injector needle to be moved upwards, the fuel injector opens and the fuel enters the combustion chamber via the spray holes.

At a certain point, the piezo actuator is deactivated by the PCM. The fuel injector piston moves back upwards and the mushroom valve closes off the control chamber. As soon as the pressure in the control chamber exceeds the pressure in the nozzle prechamber, the fuel injector needle closes off the spray holes and injection ends.